ACCURATE MEASUREMENT OF INVENTORY CAN SAVE AGGREGATES PRODUCERS TIME AND MONEY.

By Mark S. Kuhar

Aggregates producers are quickly finding out that automated drone systems can improve how a company measures aggregate stockpiles, and save them a lot of money.

Like many aggregate companies, Whitaker Contracting and Madison Materials have measured stockpiles for decades using a combination of employees on the ground and third-party surveyors, per the following:

- Employee – Each of the three sites has 30 large stockpiles, and it took a full week to collect and analyze each site. Surveys happened 4 times per year and resulted in 576 annual man hours, at $30 per hour and $17,280 annual employee time cost.

- Equipment – Finance team estimated that the survey and GPS equipment costs the company $11 per hour, which is another $4,752 annual equipment cost.

- Third Party – Whitaker also hired third-party surveyors to assist with stockpile measurements, mostly with end-of-year inventory, and did one survey by ground at a cost of $4,800, and one survey by air at a cost of $11,000, or a $15,800 total annual cost for third-party measurement.

Combined, the previous annual cost of measuring the Whitaker stockpiles was $37,832 with a six-times-per-year frequency.

New Method

New Method

With the Kespry Automated Drone System, Whitaker pays for the system up-front and then can measure as many sites and stockpiles as they want on their own. The new process is faster and cheaper, according to the company.

- Employee – The same employee flies the Kespry automated drone over each site, taking just a few hours per site, so Whitaker has increased their stockpile measuring frequency to 12 times per year, resulting in 144 annual man hours at $30 per hour and $4,320 annual employee time cost.

- Equipment – The annual cost of the Kespry Drone System was $25,000 for all the integrated hardware and software components, including unlimited flights, data analysis, data storage communications, online storage, maintenance and support.

- Third Party – After using Kespry’s Drone System, Whitaker no longer has the need to hire third-party surveyors.

Clear ROI

Combined, the new annual cost to Whitaker is $29,320 which is 22 percent less than before, and Whitaker is now able to measure their stockpiles 2 times more frequently, while spending 4 times less time overall. The Kespry Automated Drone System has clearly paid for itself on just stockpile measurement efficiency and savings, the company said.

Other Benefits

Other Benefits

The leader at Whitaker on this drone project has been John Davenport, who in a short amount of time has become an industry expert on drones, advising not only peer companies about his experiences, but sharing valuable information back to Kespry to improve their product.

Along the way, John has uncovered some other real and exciting benefits from drones, well beyond the initial cost savings.

- Safety and Inspection – Aggregate stockpiles and cliff faces are dangerous to climb and inspect, so Whitaker is much happier to have John safe on the ground while the drone flies overhead. It’s safer, faster and easier for everyone – especially in Alabama’s heat and rain.

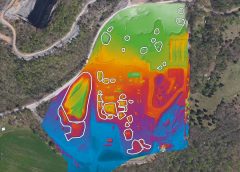

- New Opportunities – John is flying the Kespry drone more than 24 times per year, with only half of those flights being for stockpile measurement. The team at Whitaker is using the Kespry Drone System for quarry inspection, mine planning and mine operations. They’re also finding the Kespry Drone to be a great tool for construction and road projects, to verify aggregate and excavation amounts. Whitaker also includes the Kespry aerial images and 3D models in their customer proposals and project updates.

In summary, Whitaker is extremely satisfied with the Kespry drone costs savings for stockpile measurement, but is even more excited about the new opportunities that Kespry drones are helping create for their business.

Other Producers Weigh In

“With the drone we can get a cost efficient and accurate measurement of our stockpiles every month, versus the quarterly measurements we were getting before,” said Mike Moy, Lehigh Hanson. In addition to measuring stockpiles, Moy next plans to use the Kespry drone system for mine planning and reclamation projects.

“The Kespry Cloud, fueled by efficient, repeatable Kespry UAV flights, allows us to quickly collect site information, process it, and deliver results to our customers,” said Mark Power, survey team leader at infrastructure-management firm Woolpert.

“We use the Kespry Drone System to measure stockpiles, manage inventory and for pit planning, as well as surveying new and existing quarry locations for construction projects across Alberta Canada,” said Chris Hendsbee, crushing operations manager for Wapiti Gravel Suppliers.

Accurate measurement of inventory ensure that you never have to write down thousands of dollars in losses, or reconcile end-of-quarter discrepancies, according to the experts at Krespy. And that is something worth thinking about.

This article is adapted from a presentation made in March 2016 at AGG1 in Nashville by David Reed (Whitaker Contracting) and Adam Rice (Kespry).